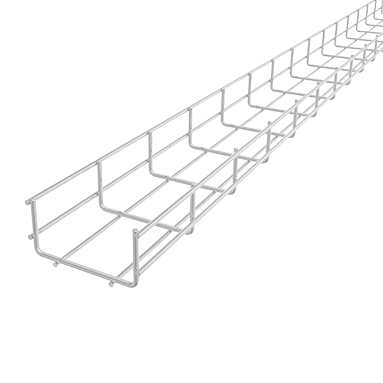

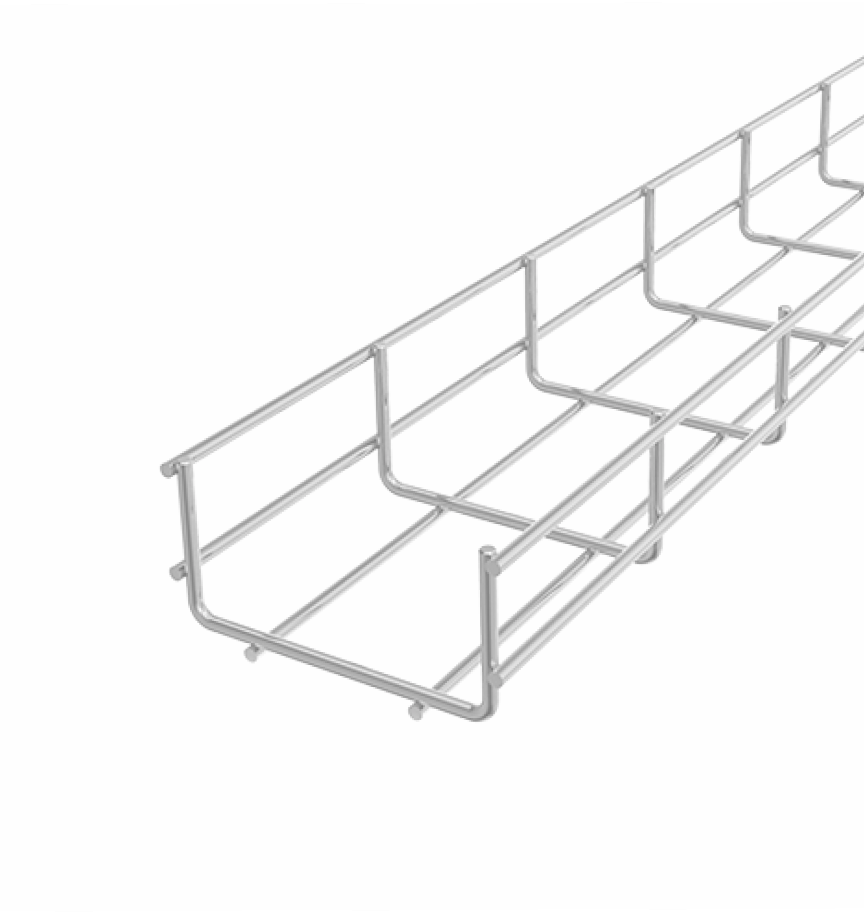

Products Cable trays

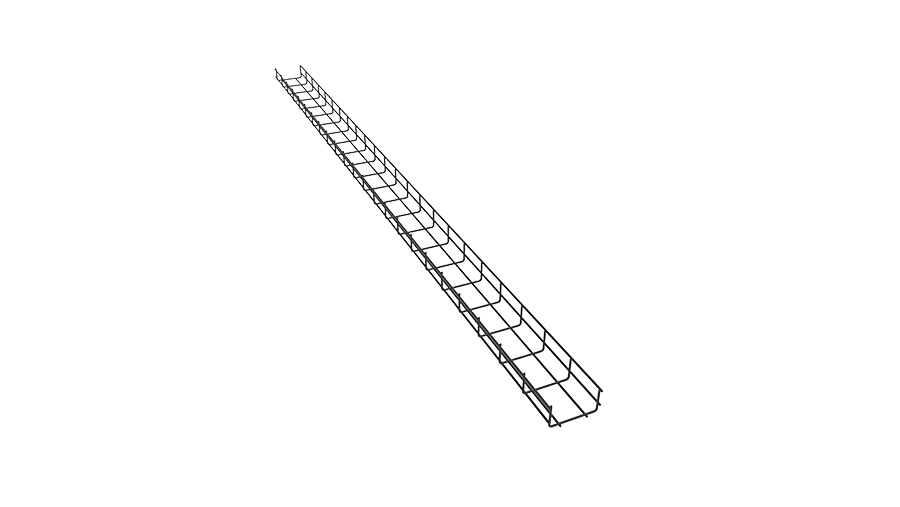

Cable trays has an overall mission: to organize cables. In order to successfully meet the market's demands, high requirements and adaptations to various industries, a broad and well-thought-out range is required. Axelent Wire Tray's cable laying system consists of wire trays sold under the X-Tray brand.

We are unique Cable trays with many advantages

-

Safety

Designed with safety in mind, our cable trays reduce the risk of accidents by providing stable support and protection for your cables.

-

Sustainability

Our cable trays are made of high-quality materials that can withstand harsh conditions and have a long lifespan, reducing the need for frequent maintenance or replacement.

-

Easy installation

The cable trays are designed to be easy to install and customise. With intuitive design features, you can save time during the installation process.

-

Flexibility

We offer different types of cable trays that can be customised to your specific application or conditions.

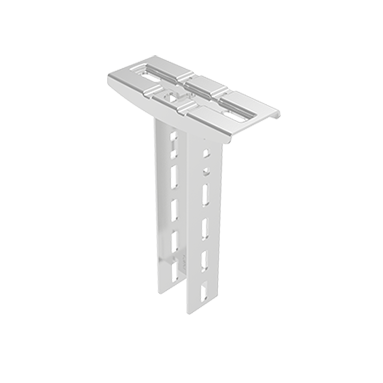

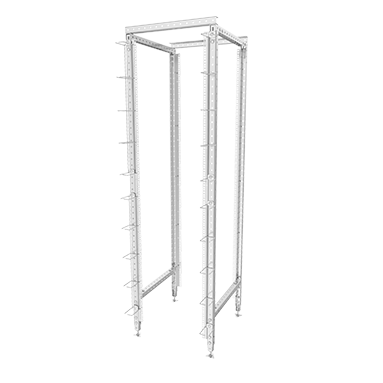

Easy installation Cable management with the longest spacing between support brackets

Fast installation is a criteria that we believe is absolutely decisive for a product to be classified as “premium”. For the X-Tray cable laying system, every detail is carefully thought out so that you, the customer, will notice the difference. X-Tray also has the market’s longest bracket distance, which facilitates assembly through fewer parts and thus also lower costs.

Certifications Cable trays suitable for the highest demands

X-Tray is a premium product that meets the very highest requirements for cable laying according to IEC 61537.

To ensure that the we keep our promise, X-Tray is continuously tested. In this way, we can guarantee high quality and that it meets the demands that the industry has on our products.

Quick deliveries Standard range in stock

Our standard range usually covers most needs and is sufficient for a complete installation. The standard range is always available in stock, in several different materials and surface treatments, which means we can guarantee fast deliveries.

In our modern, flexible machine park, we can also customize and produce exactly the wire trays needed for each unique project. Don’t let standard measurements limit you. Ask us and we will help you find a specially adapted solution with optimal function based on your needs.

Smart packaging Cable management where the details make a difference

When you buy cable management system from Axelent Wire Tray, you should feel that the system has been thought through down to the last detail. And we know that it’s the little details that make the difference! An example of this is the specially designed bags that all the small parts are delivered in. They are used to make it easier for you during assembly by keeping all the parts in the bag and being easily accessible during assembly.